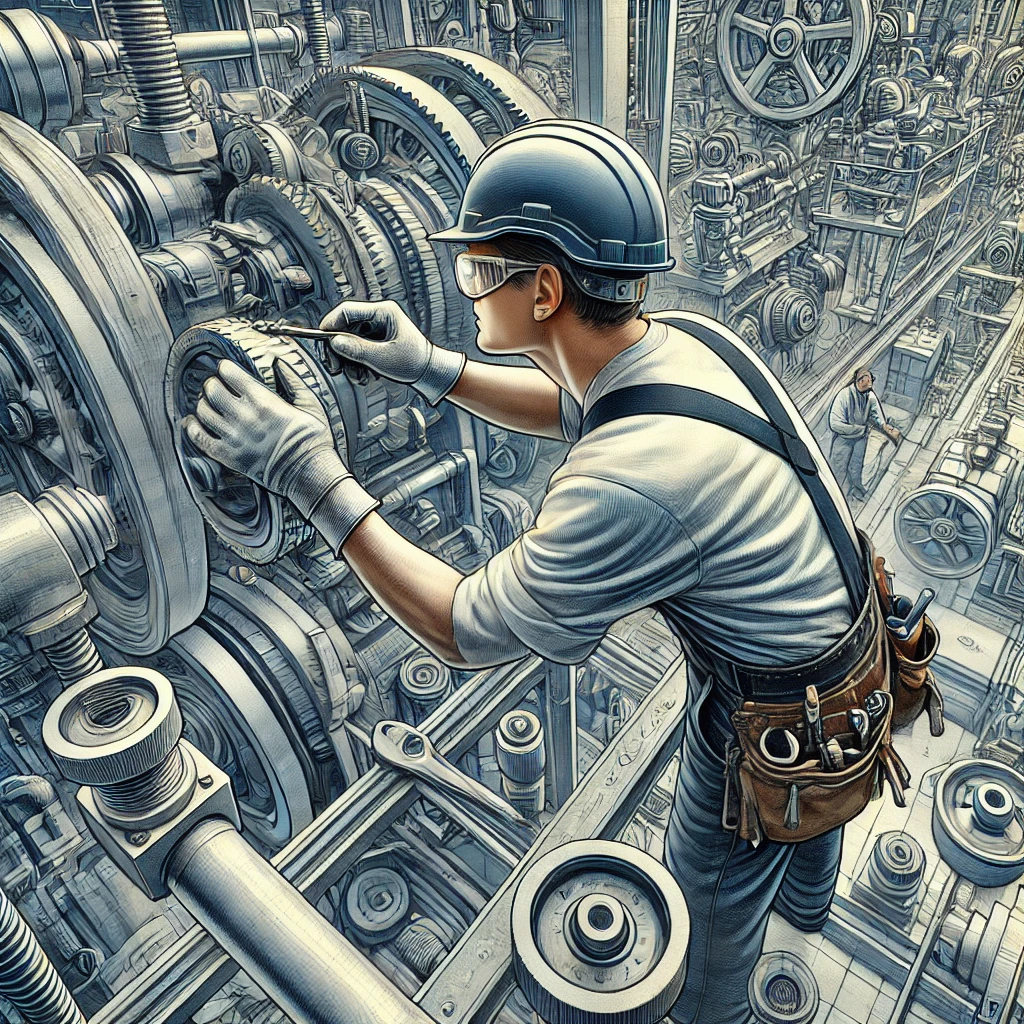

What Do Millwrights Do?

Millwrights play a crucial role in industrial settings, specializing in the installation, maintenance, and repair of machinery used across various sectors. From manufacturing plants to power stations, millwrights ensure that complex machines and equipment run smoothly, efficiently, and safely. In this guide, we’ll cover the duties, skills, and industry contributions of millwrights, as well as the training and certifications required to excel in this trade.

1. Primary Responsibilities of a Millwright

Millwrights handle a broad range of tasks that focus on setting up and maintaining industrial machinery. Their duties vary based on the industry they work in, but some of the core responsibilities include:

- Installing Machinery and Equipment: Millwrights install heavy machinery, ensuring that it’s correctly positioned, anchored, and calibrated. They align and level machines, connecting components like pumps, motors, and conveyors to guarantee efficient performance.

- Maintaining Equipment: Regular maintenance is crucial for preventing breakdowns, and millwrights perform routine inspections, lubrication, and part replacements. They keep equipment in top condition, extending the lifespan of machinery and avoiding costly downtime.

- Troubleshooting and Repairing Machinery: When machinery malfunctions, millwrights diagnose the problem, make necessary repairs, and test the equipment to ensure it operates correctly. Their troubleshooting skills help identify issues before they lead to significant breakdowns.

- Dismantling and Relocating Equipment: Millwrights are often responsible for dismantling machinery for repair or relocation within a facility. They handle equipment safely, following strict procedures to avoid damage.

- Reading Blueprints and Schematics: Millwrights use technical blueprints, diagrams, and schematics to understand the structure of machinery, guiding them in installation, maintenance, and troubleshooting.

2. Skills and Knowledge Required to Be a Millwright

Millwrights require a unique combination of mechanical, technical, and physical skills to perform their duties effectively. Here are some key skills that make a successful millwright:

- Mechanical Aptitude: Millwrights need a strong understanding of mechanical systems, including hydraulics, pneumatics, and electricity. This knowledge helps them work with diverse types of machinery across various industries.

- Technical Precision: Installing and aligning machinery requires high precision. Millwrights use tools like micrometers and laser alignment devices to ensure machines are correctly positioned for optimal performance.

- Problem-Solving Abilities: Millwrights frequently encounter mechanical issues that require quick, effective solutions. Their ability to troubleshoot and resolve problems minimizes equipment downtime and maintains productivity.

- Physical Stamina and Strength: Millwrights often work in challenging environments, lifting heavy parts, working in confined spaces, and standing for extended periods. Physical fitness is essential for performing their tasks safely.

- Attention to Safety: Millwrights prioritize safety in their work, as they handle heavy machinery and complex equipment. They follow safety protocols, wear personal protective equipment, and stay informed on safety regulations.

3. Industries That Rely on Millwrights

Millwrights work across a variety of industries, each with specialized machinery and equipment that requires expert handling. Here are some sectors that depend heavily on millwrights:

- Manufacturing: Manufacturing plants rely on millwrights to set up and maintain production lines, ensuring machines function efficiently to meet production targets. Millwrights keep assembly lines running smoothly and perform preventative maintenance to avoid interruptions.

- Energy and Utilities: Power plants and utilities require millwrights to install and repair turbines, pumps, and generators. These machines are vital for power generation, so millwrights’ work ensures uninterrupted energy production.

- Mining and Natural Resources: In mining, millwrights manage equipment like crushers, conveyor belts, and elevators. Their work helps extract and process materials efficiently, supporting the mining industry’s productivity.

- Food Processing: The food industry uses specialized machinery for sorting, packaging, and processing products. Millwrights ensure this equipment operates within strict hygiene and efficiency standards, supporting food safety and quality.

- Construction and Heavy Equipment: Millwrights assist in setting up heavy equipment for construction projects, ensuring machinery like cranes and excavators are installed correctly and operate safely.

4. Becoming a Millwright: Training and Certification

To become a millwright, individuals typically complete a combination of classroom education, hands-on training, and certification. Here’s a breakdown of the steps to become a qualified millwright:

- Educational Requirements: Most millwrights start with a high school diploma, focusing on subjects like mathematics, physics, and mechanical drawing. Some pursue further education at technical schools or colleges to gain foundational knowledge in industrial mechanics.

- Apprenticeship Programs: In Canada, aspiring millwrights complete a multi-year apprenticeship program that combines on-the-job training with classroom learning. During this time, apprentices learn key skills under the supervision of experienced millwrights.

- Certification: After completing an apprenticeship, millwrights often seek certification, such as a Red Seal in Canada, which recognizes their skills across the country. Certification helps validate their expertise and can lead to higher earning potential.

- Ongoing Education: Many millwrights pursue additional training to stay updated on new technologies and machinery. Continuous learning keeps them adaptable and competitive within their field.

5. Tools and Equipment Millwrights Use

Millwrights use specialized tools and equipment to handle machinery safely and accurately. Some of the essential tools they work with include:

- Alignment Tools: Millwrights use micrometers, dial indicators, and laser alignment tools to position and align machinery with high precision.

- Hand and Power Tools: Wrenches, screwdrivers, and drills are commonly used for assembling, disassembling, and adjusting machinery.

- Welding and Cutting Equipment: Millwrights often need to weld or cut metal parts, so they use tools like torches and welders to modify or repair components as needed.

- Lifting Equipment: Cranes, hoists, and forklifts help millwrights move heavy machinery and parts, allowing them to position equipment safely.

6. The Importance of Millwrights in Modern Industry

Millwrights are essential for keeping industries productive and safe. Their ability to maintain and repair machinery minimizes downtime, supports production targets, and extends the lifespan of equipment. Additionally, millwrights’ expertise in installation helps companies adapt to new technologies, improving efficiency and output.

7. Challenges Millwrights Face in Their Work

Working as a millwright comes with unique challenges. Millwrights often work in noisy, high-pressure environments where they must handle complex machinery. Physical strain, potential hazards, and tight deadlines can create demanding work conditions. However, the rewards, including high job satisfaction and competitive pay, make the career appealing for those who enjoy hands-on work and mechanical problem-solving.

Frequently Asked Questions About Millwrights

- Is a millwright the same as a mechanic?

While both work with machinery, millwrights focus more on the installation, alignment, and movement of large equipment, whereas mechanics primarily repair and maintain existing equipment. - Do millwrights work indoors or outdoors?

Millwrights work in both indoor and outdoor settings, depending on the industry and project. They adapt to different environments, from factories to construction sites. - How long does it take to become a certified millwright?

In Canada, becoming a certified millwright typically takes around 4-5 years, including apprenticeship training and any certification requirements.

Conclusion

Millwrights bring valuable skills to diverse industries, ensuring that machinery operates safely, efficiently, and reliably. Their expertise in installation, maintenance, and repair supports production and helps businesses achieve their goals. If you’re considering a career as a millwright or want to learn more about the trade, understanding their role reveals the significance of these skilled professionals in modern industry.